Material Review Board: Definition And Benefits

The Material Review Board (MRB) is just a team of experts within a wide range of areas that include planning, manufacturing, stress, design, quality, among many others. This is what is called a cross-functional team and the Material Review Board usually meets on a weekly or monthly basis.

Get the best Six Sigma training for free.

Get the best Six Sigma training for free.

The main goal of the Material Review Board is to meet to decide about any critical deviation that can't be dispositioned outside this group. One of the things that you need to understand is that we just can't define these deviations in a specific way. All we can say about them is that they do not conform to a specification or standard of a specific assembly, part, or the materials that are associated.

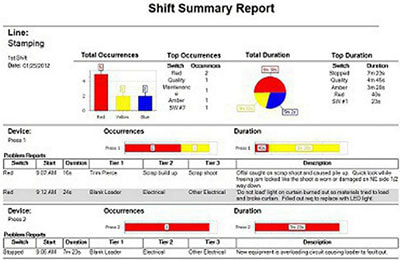

When the Material Review Board meets, they will then decide about what they will do with the non-conformity. The Material Review Board will begin by documenting the non-conformity that was discovered in a Non-Conformity Report (NCR) which is simply a document that allows the tracking of all the deviations. Each NCR reports only one deviation.

Discover the basic Six Sigma metrics.

The job of the Material Review Board is then to analyze the NCR and they then decide about what they need to do. Here are the options:

Discover the basic Six Sigma metrics.

The job of the Material Review Board is then to analyze the NCR and they then decide about what they need to do. Here are the options:

#1: Use As Is:

The first option that the Material Review Board can make is to state that the material or part should continue to be used without any change.

The Material Review Board can only apply this disposition after they confirm that the part or material won't affect the rest of the process in any way.

Check out our complete lean six sigma glossary.

The Material Review Board can only apply this disposition after they confirm that the part or material won't affect the rest of the process in any way.

Check out our complete lean six sigma glossary.

#2: Repair Or Rework:

The second option that the Material Review Board can is to order for the part or material to be repaired so it can be used again.

In order to make this decision, the Material Review Board needs to first confirm that the part is able to handle all the stress during the process and that it will be able to comply with all the regulations.

In order to make this decision, the Material Review Board needs to first confirm that the part is able to handle all the stress during the process and that it will be able to comply with all the regulations.

#3: Scrap:

The last option that the Material Review Board has is to simply discard or scrap the part. Usually, this is the last option that the Material Review Board decides to take since it means that the part or material includes a major flaw that just can't be reworked or repaired and can't be used as is without interrupting the process.

Learn more about the Central Limit Theorem.

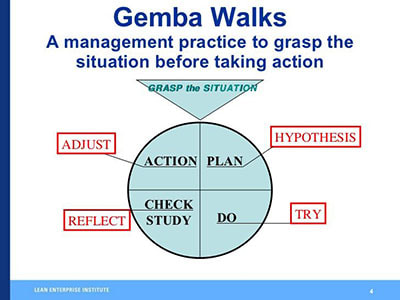

While it may seem that the Material Review Board isn't really a crucial piece within your organization, you should consider this better. After all, including a Material Review Board within your organization can bring a lot of benefits to the organization that include:

Learn more about the Central Limit Theorem.

While it may seem that the Material Review Board isn't really a crucial piece within your organization, you should consider this better. After all, including a Material Review Board within your organization can bring a lot of benefits to the organization that include:

- The improvement of the process by knowing the causes and the rework rates.

- The shipping of the products will be done sooner.

- There is a save in time and cost to process rework.

- It makes the determination of the labor costs of rework easier and more transparent.

- You will have real-time data about the parts that need to be reviewed and that are designated for rework as well as you will know where these parts are in the rework process.

RSS Feed

RSS Feed