When you have a business, then it is likely that you have been reading about Six Sigma. However, and since this approach has been being applied for such a long time, you may b wondering if it is still effective.

Learn Six Sigma for free.

Learn Six Sigma for free.

Besides, as it happens with everything in life, it's hard to please everyone. And Six Sigma is no different. The truth is that there are many critics who have been questioning the wisdom of relying a lot on Six Sigma. Joining these critics are business owners who have failed to implement this approach within your organization.

A Brief History Of Six Sigma

In case you don't know, Six Sigma started being discussed in the 1980s and many manufacturers started applying it right away as a way to reach the zero-defect ideal.

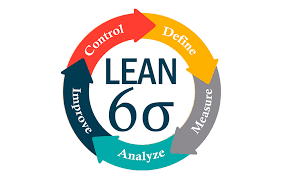

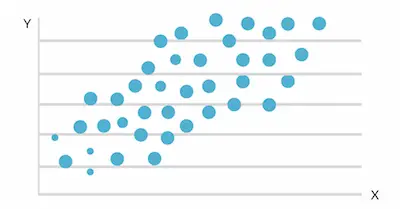

When you look at Six Sigma at a high level, you need to keep in mind that it uses the DMAIC (define, measure, analyze, improve, and control) cycle to eliminate process variation. This way, you should reduce product defects since you are making all processes predictable and consistent. Obviously, this would lead to substantial cost quality reductions for the ones implementing it.

Check out this brief introduction to Six Sigma.

The reality is that when multi-billion dollar companies decided to use Six Sigma within their organizations, these companies were able to save billions of dollars.

When you look at Six Sigma at a high level, you need to keep in mind that it uses the DMAIC (define, measure, analyze, improve, and control) cycle to eliminate process variation. This way, you should reduce product defects since you are making all processes predictable and consistent. Obviously, this would lead to substantial cost quality reductions for the ones implementing it.

Check out this brief introduction to Six Sigma.

The reality is that when multi-billion dollar companies decided to use Six Sigma within their organizations, these companies were able to save billions of dollars.

Statistically speaking, a Six-Sigma level of quality should theoretically achieve 99.9997% yield and equate to 3.4 defects per million opportunities. If these numbers make you raise an eyebrow and wonder precisely where these figures come from, you are not alone in your skepticism. Without delving into the intricacies behind the mathematics too deeply, Six Sigma statistical methods hinge on a standard deviation of plus/minus 1.5, the "Six-Sigma shift." As such, the fundamental veracity of its statistical presumptions has been questioned time and time again.

The Main Criticisms Of Six Sigma Today

While many companies (both large and small) have already experienced success when they implemented the Six Sigma method, the reality is that not all have succeeded. And there are some main criticisms that are made to the Six Sigma approach.

The main criticisms of Six Sigma today include:

#1: Six Sigma as a one-dimensional philosophy:

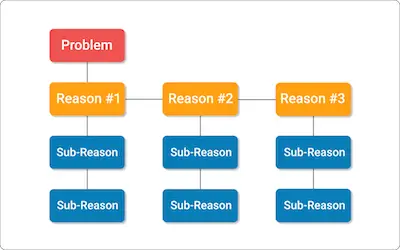

According to this argument, the cost reductions that Six Sigma allows are too narrow. Besides, it also includes the fact that not all quality management woe can be separated in terms of quality metrics.

These are the basic Lean Six Sigma metrics.

These are the basic Lean Six Sigma metrics.

#2: Six Sigma as a short-sighted business approach:

According to this critic, and even though most business owners agree that Six Sigma can bring cost reductions in the short-term, it is also true that in some cases it may lead to a proverbial wall.

#3: Six Sigma as an outsourced service:

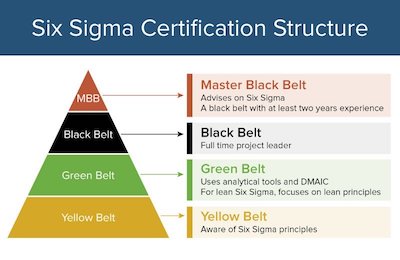

The last main criticism made to Six Sigma is the fact that it only serves to hire outsourced companies and individuals who need to be certified as Black Belts or Master Black Belts. And this can be a very problematic process.

Discover why you should get Six Sigma certification.

Discover why you should get Six Sigma certification.

Is Six Sigma Still Relevant Today?

In our opinion, yes, Six Sigma continues to be incredibly relevant nowadays. And the main reason is due to the fact that any new manufacturer (or quality manager) hopes to gain credibility as a high-quality business partner. Besides, its continuous improvement philosophy aligns with ISO 9001 standards well. However, it needs context. After all, we also believe that Six Sigma isn't applicable to every quality issue.

RSS Feed

RSS Feed