Kanban

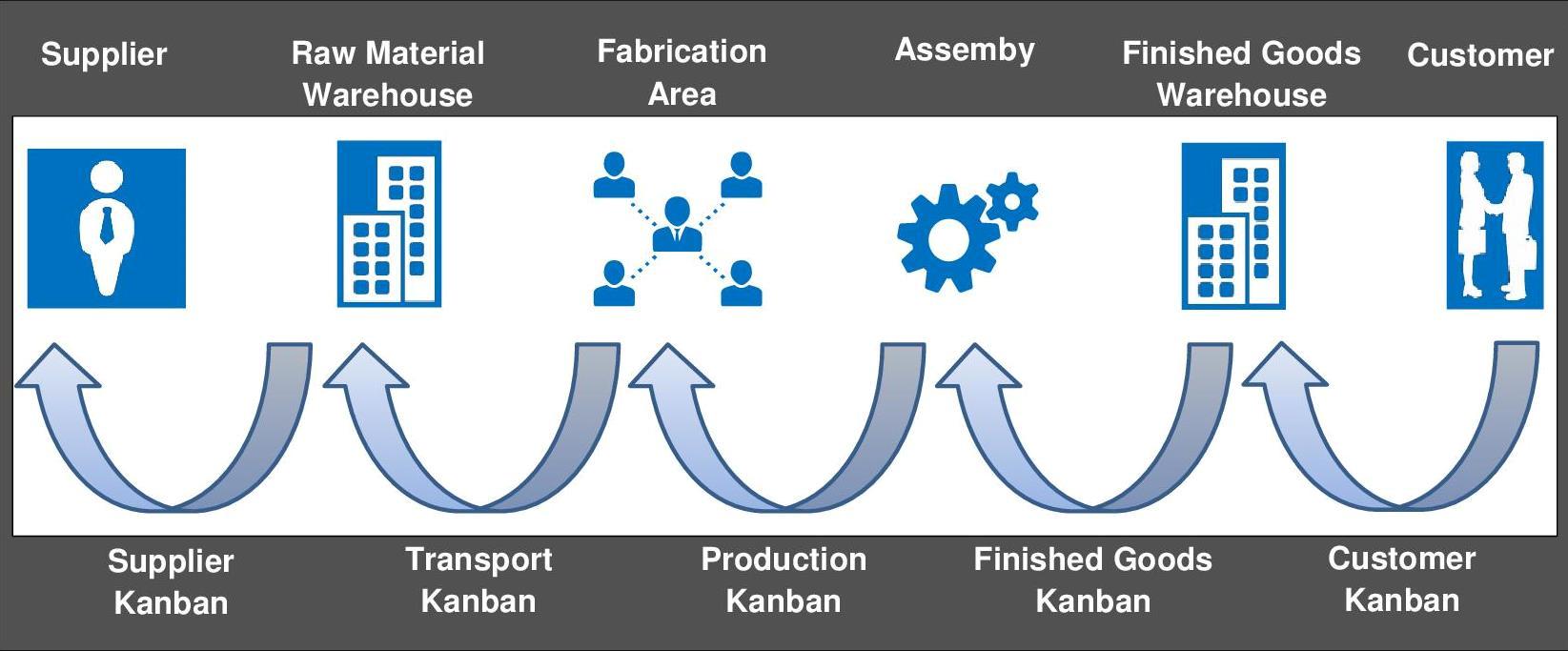

The kanban is a system used in Lean Production. The kanban main goal is to reduce the inventory and, at the same time, force the different stations to be more efficient, responsive, and ready to make changes when necessary.

When you're using the kanban, you'll have the products divided into small batches to meet the immediate demand. They are only produced when there is demand; when there's no demand, the stations stop working, avoiding the inventories. You can say that the production is constantly adapting to the demand itself. If it increases production increases, if it decreases, the production decreases as well, and if there's no demand, the production stops.

When you're using the kanban, you'll have the products divided into small batches to meet the immediate demand. They are only produced when there is demand; when there's no demand, the stations stop working, avoiding the inventories. You can say that the production is constantly adapting to the demand itself. If it increases production increases, if it decreases, the production decreases as well, and if there's no demand, the production stops.