Failure Mode & Effects Analysis (FMEA)

When you're looking to evaluate risk, the Failure Mode & Effects Analysis (FMEA) is a good choice.

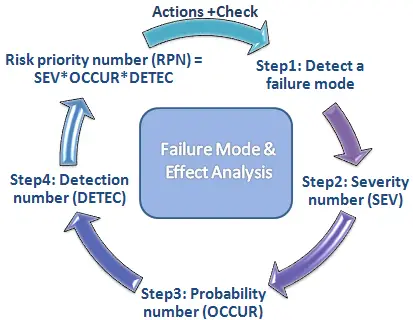

The Failure Mode & Effects Analysis (FMEA)evaluates each potential failure mode for 3 different situations:

- S - The severity of the consequences in the case it occurs.

- O - The probability it has to occur.

- D - The probability of being detected before the shipping.

Each one of these 3 situations is rated on a scale that ranges from 1 to 10. Then, in order to find the Risk Priority Number (RPN), the 3 values are multiplied. In case the RPN is above a specified number, you'll need to act to reduce it.

The Failure Mode & Effects Analysis (FMEA) is most often used as the basis of the control stage in a Six Sigma project.

The Failure Mode & Effects Analysis (FMEA)evaluates each potential failure mode for 3 different situations:

- S - The severity of the consequences in the case it occurs.

- O - The probability it has to occur.

- D - The probability of being detected before the shipping.

Each one of these 3 situations is rated on a scale that ranges from 1 to 10. Then, in order to find the Risk Priority Number (RPN), the 3 values are multiplied. In case the RPN is above a specified number, you'll need to act to reduce it.

The Failure Mode & Effects Analysis (FMEA) is most often used as the basis of the control stage in a Six Sigma project.