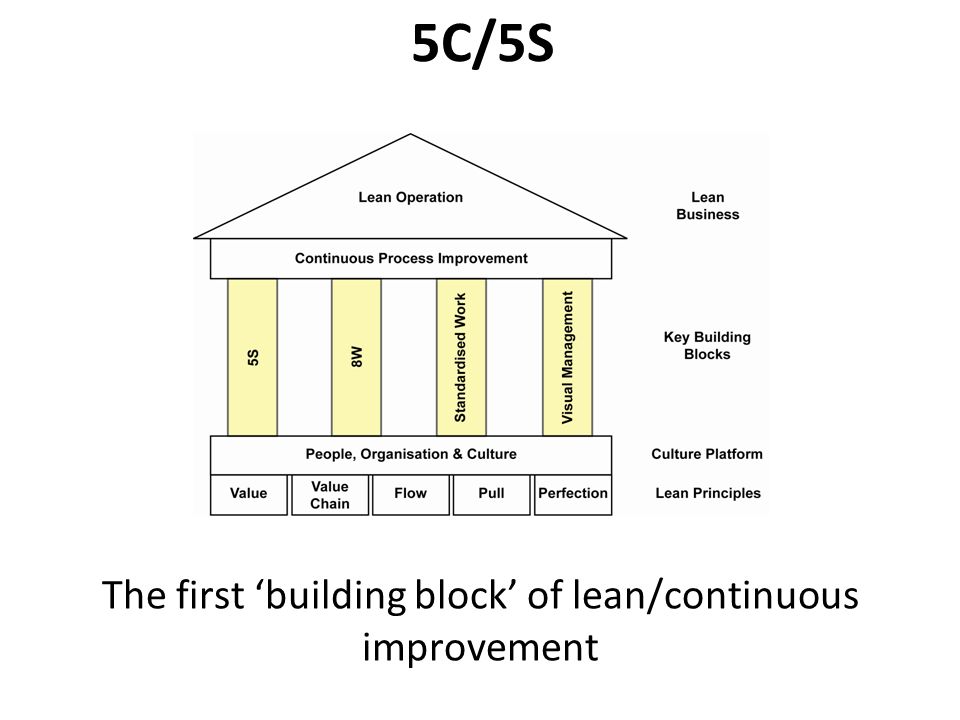

5C

The 5C is a very similar technique to the 5S that is used to stabilize and improve the best and safest work environment, in order to support a sustainable cost, quality, and delivery.

The 5Cs are:

- Clear Out - In this stage, you need to separate what's essential from what's not essential

. Configure - In this stage, you need to find a place to put everything and everything should be in its place

- Clean and Check - In this stage, you need to make a deep cleaning to make sure you don't see any abnormal conditions

- Conformity - In this stage, you need to make sure that the standards are not only maintained as they are also improved

- Custom and Practice - In this stage, everyone already knows the rules and follows them. They completely understand the benefits of the changes and they're contributing positively to the improvement.

The 5Cs are:

- Clear Out - In this stage, you need to separate what's essential from what's not essential

. Configure - In this stage, you need to find a place to put everything and everything should be in its place

- Clean and Check - In this stage, you need to make a deep cleaning to make sure you don't see any abnormal conditions

- Conformity - In this stage, you need to make sure that the standards are not only maintained as they are also improved

- Custom and Practice - In this stage, everyone already knows the rules and follows them. They completely understand the benefits of the changes and they're contributing positively to the improvement.