The Hoshin Kanri Planning Process

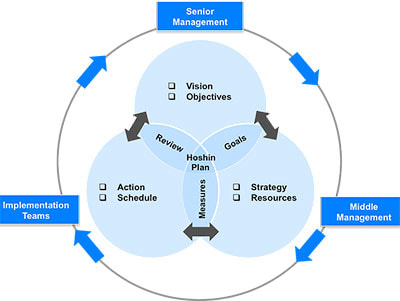

The Hoshin Kanri planning process is a management methodology that is based on the ideas of Professor Yoji Akao and it was popularized in Japan back in the 1950s. According to the Professor, "Each person is the expert in his or her own job, and Japanese TQC [Total Quality Control] is designed to use the collective thinking power of all employees to make their organization the best in its field."

Discover all you need to know about Six Sigma.

Discover all you need to know about Six Sigma.

Based on these ideas, the Hoshin Kanri planning process shows the way an organization should drive its action every day to reach their strategic goals. So, in Hoshin Kanri words, this means to make everyone committed to working towards in the same direction known as the "true north".

The 5 Principles Of the Hoshin Kanri Planning Process:

The 5 Principles Of the Hoshin Kanri Planning Process:

#1: The Performance:

The organization needs to have a clear leader that can help everyone move towards the ultimate goals or the True North. These include the identification of bottlenecks as well as potential issues.

#2: Communication:

Communication is a crucial principle within the Hoshin Kanri planning process. After all, without a clear communication from the leader, there isn't a common goal and vision.

#3: Analyze The Present Situation:

According to the Hoshin Kanri planning process, it is crucial that the organization knows exactly where they stand at the moment so they can understand how they can improve. With this in mind, it is important that transparency is kept at a high level so that all the efforts can be put on improving the KPIs.

#4: Using The Right Resources:

While you should be able to find a lot of areas within your organization that need improvement, it is important that the management knows how to prioritize them. So, it is important that you create a custom weighted scoring system that allows you to easily evaluate the priority, risks, and complexity of a specific improvement.

#5: Increasing The Engagement:

This is another important principle of the Hoshin Kanri planning process. After all, it is important that everyone within the organization is truly committed and engaged in achieving the True North goals.

While the Hoshin Kanri planning process may sound very easy, the truth is that many organizations need to complete a series of steps in order to completely adopt the Hoshin Kanri methodology.

So, if you are considering implementing the Hoshin Kanri planning process in your organization, here are the Hoshin Kanri steps that you should follow:

While the Hoshin Kanri planning process may sound very easy, the truth is that many organizations need to complete a series of steps in order to completely adopt the Hoshin Kanri methodology.

So, if you are considering implementing the Hoshin Kanri planning process in your organization, here are the Hoshin Kanri steps that you should follow:

Step #1: Establish the Vision and Know The Current Situation

During the first step, it is crucial that you check the values, vision, and mission of the company and see if they are aligned with what you want for your organization. This is the time that you have to look at the different processes and see if there are any changes that need to be made so that you can reach your future goals as well as what is working well.

Here are some of the questions that you should be able to answer during this step:

Here are some of the questions that you should be able to answer during this step:

- What are your long-term plans?

- What is your current mission and vision of the organization?

- How does your daily management system work and how does your organizational structure work?

- What procedures and policies are already in place and what are the ones that need to be rearranged or to be eliminated?

Step #2: Come Up With Breakthrough Objectives

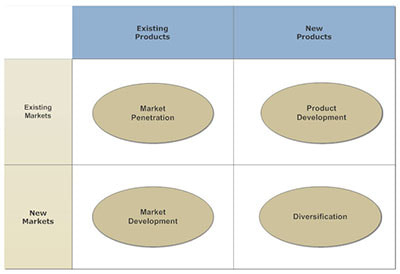

Simply put, breakthrough objectives are the goals that will allow your organization to be challenged in different ways and they usually take between 3 to 5 years to reach. Some breakthrough objectives can include the adoption of a different service delivery model, introducing new products, entering new markets, among many others.

During this step, you can use different tools to help you identify growth opportunities. One of the tools that tend to be more used is the four quadrant of growth that is a simple adaptation of the Ansoff Matrix. By using this tool (or a similar one), you will be able to discover objectives in different areas by comparing consumers and non-consumers (the people who are currently using your services or products and the ones who aren't) and the current and new jobs that you may require.

During this step, you can use different tools to help you identify growth opportunities. One of the tools that tend to be more used is the four quadrant of growth that is a simple adaptation of the Ansoff Matrix. By using this tool (or a similar one), you will be able to discover objectives in different areas by comparing consumers and non-consumers (the people who are currently using your services or products and the ones who aren't) and the current and new jobs that you may require.

Step #3: Set Up Annual Objectives

Setting up annual objectives is also important since it will help you reach your breakthrough objectives within the 3 to 5 years. Let's say that you want to launch a new product. So, one of your annual objectives may be to make a complete market research study as well as to define all the product requirements.

These are the basic Six Sigma metrics you should know.

These are the basic Six Sigma metrics you should know.

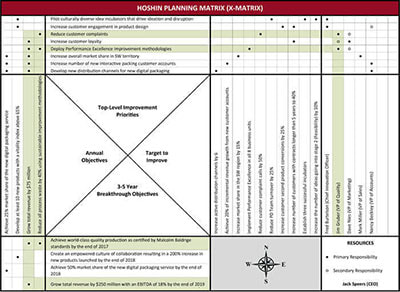

Step #4: Using Workable Targets

Now that you already defined the breakthrough objectives as well as the annual objectives that you need to have to reach the first ones, it is now the time to determine what each team, department, and individual need to accomplish. One of the things that you need to have in mind is that the goals that you define need to be measurable and should be able to be closely monitored by leadership.

One of the tools that tend to be used during this step os the Hoshin Planning Matrix also known as the X Matrix. This tool allows you to immediately know all the objectives as well as cascading priorities. In addition, you can also use value stream maps and summary reports that can help you manage the progress towards the goals that you have defined.

Discover more about value stream mapping.

Discover more about value stream mapping.

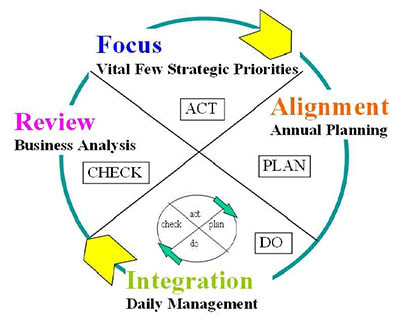

Step #5: Execute Annual Objectives

This is the step on which you start with the improvements that will allow you to reach your yearly goals. In order to achieve them, you can use a wide variety of tools that include A3, PDSA, DMAIC, Kaizen events, among others.

Step #6: Keep Monthly Tracks

One of the most common mistakes organizations make when they are using the Hoshin Kanri planning process is that they focus all the energy on the yearly goals and they forgot to keep track on what is being done each month. So, by having monthly reviews, the Hoshin Kanri planning process avoids this mistake ensuring that the forward progress is being maintained.

Take a look at the best free courses you can take online.

Take a look at the best free courses you can take online.

Step #7: Annual Review

By the end of the year, it is now time to make the annual review. This consists in assessing the entire organization's progress.

During this time, you need to discover if there is any need to make adjustments to times and goals that were previously defined as well as it is the perfect time to ensure that all the resources are well allocated.

During this time, you need to discover if there is any need to make adjustments to times and goals that were previously defined as well as it is the perfect time to ensure that all the resources are well allocated.

RSS Feed

RSS Feed