Common & Special Cause Variation

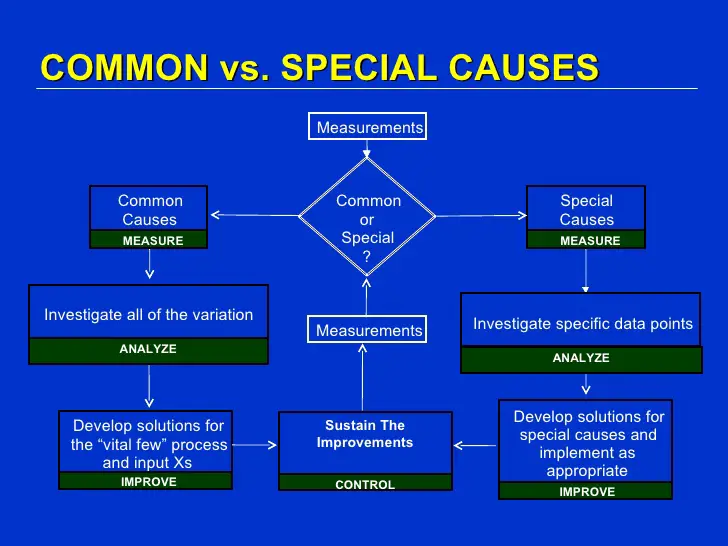

There are two different categories of cause variation: common cause variation (general) and special cause variation (assignable).

The common cause variation occurs when several small factors affect the process. The common cause variation can only decrease when there are changes made to the system, and they usually imply action from the management. A simple example would be a machine upgrade.

The special cause variation occurs when there are specific factors that produce a certain result in the process itself. The special causes can, in most cases, be identified and eliminated without a significant change in the process. A simple example of a special variation cause is the improvement of the raw materials or simply fixing a fault on a machine.

The common cause variation occurs when several small factors affect the process. The common cause variation can only decrease when there are changes made to the system, and they usually imply action from the management. A simple example would be a machine upgrade.

The special cause variation occurs when there are specific factors that produce a certain result in the process itself. The special causes can, in most cases, be identified and eliminated without a significant change in the process. A simple example of a special variation cause is the improvement of the raw materials or simply fixing a fault on a machine.