Six Sigma Project Examples You Should Consider

When you are looking at the Six Sigma methodology for the first time or if you don't really understand how to use Six Sigma in practice, there is nothing better than checking out some six sigma project examples.

Discover everything you need to know about Six Sigma projects.

When you are looking for a good project, you should follow some guidelines:

Discover everything you need to know about Six Sigma projects.

When you are looking for a good project, you should follow some guidelines:

- You shouldn't have a pre-determined solution for the project.

- You should be able to easily identify the process inputs and outputs.

- When you are looking at a Six Sigma project, you need to make sure that you ate able to put yourself in a perspective where you can understand the variation in the process inputs. In addition, you need to be able to control them and eliminate the defects.

- In case you already know the answer, all you need to do is to apply it.

Check out our free Six Sigma training.

Now that you have some basic guidelines about Six Sigma projects, it's time to check out some six sigma project examples.

#1: Internal Defects:

When you are looking for internal defects in the process, you should consider looking at anything that you can recycle or rework in-house, as well as any scrap materials, parts or issues.

#2: External Defects:

This is another area of the process that is usually up for a Six Sigma project. In this case, you should look for anything that hasn't been rejected or audited by you but you know that it doesn't meet regulations, anything that you can cover for by having someone in the customer's plant, or even anything that you can inspect and that contains to protect the customer.

Do you need a Six Sigma certification?

Do you need a Six Sigma certification?

#3: Efficiency:

When you are looking for the best six sigma project examples, you should definitely consider taking a look at the efficiency of the processes that your organization uses. These can include a lot of things: a process with freight costs, a process where you are running slower than what you anticipated or expected, a process that requires added labor to make the required cycle, a machine or process with downtime, and when you are making fewer parts than expected.

#4: Materials Use:

When you notice that a process is using more material or that the amount of material varies is also suited for a six sigma project.

#5: Understanding What IS Behind The Process Variation:

When you have materials incoming, you should definitely try to discover whether there is a variation as well as how big this variation is. The truth is that this can have a huge impact on the output. In addition, you can also apply Six Sigma to determine if there is a way that you can compensate for these changes (by controlling other variables), among others.

Discover everything you need to know about Kaizen and Kaizen Blitz.

Discover everything you need to know about Kaizen and Kaizen Blitz.

#6: Maintenance:

Having all the machines working properly is one of the best uses that you can give to Six Sigma. After all, if you are able to have all the machines working without interruptions, you will end up with the output that you anticipated. So, you should look for ways that can prevent a high replacement cost as well as a high failure rate.

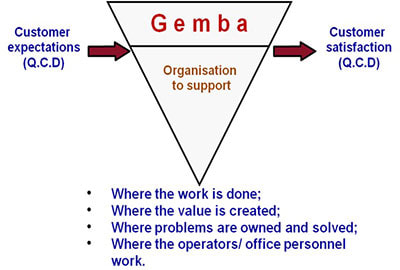

One of the best things that you can do to choose a good Six Sigma project is by using the Gemba walk. In case you are not familiar with the term, all you need to do is that it is a process that is based on the personal observation of work where it is happening. So, instead of sitting in a conference room and discussing what might be doing wrong or what could be done in a better way is to go directly to the source and observe directly what is happening. The Gemba walk has been used successfully by Toyota for many years.

One of the best things that you can do to choose a good Six Sigma project is by using the Gemba walk. In case you are not familiar with the term, all you need to do is that it is a process that is based on the personal observation of work where it is happening. So, instead of sitting in a conference room and discussing what might be doing wrong or what could be done in a better way is to go directly to the source and observe directly what is happening. The Gemba walk has been used successfully by Toyota for many years.

RSS Feed

RSS Feed