As you already know, Lean Six Sigma is the fusion or combination of Lean Manufacturing with Six Sigma. his complex system goal is to allow you to remove wastes and reduce process variation for streamlined manufacturing and optimal product output.

Learn more about Six Sigma.

Learn more about Six Sigma.

One of the things that you need to keep in mind about Lean Six Sigma is the fact that it uses Six Sigma processes and methods as the backbone of the system to drive focused improvements in manufacturing while incorporating many techniques and tools from Lean to reduce wasteful steps and processes.

The Tools Of Lean Six Sigma

#1: The 5 Whys:

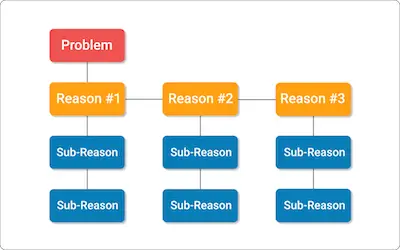

The 5 Whys is the first tool of Lean Six Sigma that you will need to use. The goal is to ensure that you can determine the root of problems within your organization.

Ultimately, you will need to start by writing down the problem you're having so that everyone in your team can focus only on it. Then, you will need to ask why it occurred. Notice that in case the first answer you get isn't the root of the problem, you will need to ask for it up to 5 times.

Understanding the 5 Whys.

#2: The 5S System:

The 5S System is another method of Lean Six Sigma that you can use to organize your workplace materials. This way, they will not only be more accessible as well as the maintenance will be easier.

Notice that this system is crucial to eliminate waste within your organization.

Simply put, the 5S's refer to:

- Seiri (Sort) – Remove all unnecessary items for your current production, leaving only what is necessary.

- Seiton (Set In Order) – Organize remaining items and label them accordingly.

- Seiso (Shine) – Clean and inspect your work area and everything in it every day.

- Seiketsu (Standardize) – Write out your standards for the Sort, Set In Order, and Shine steps above.

- Shitsuke (Sustain) – Apply the standards you’ve set for your company and make them habits for everyone in your organization.

Discover the 6 big losses of lean manufacturing tools.

#3: Value Stream Mapping:

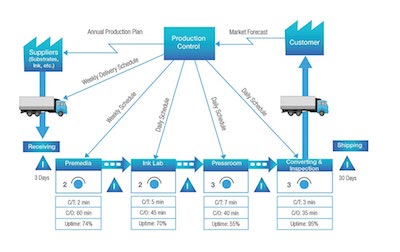

Another tool of Lean Six Sigma that you can use is value stream mapping.

Simply put, the value stream map shows you the flow of information and materials in each one of your processes. This allows you to get a better perspective of your workplace and improve and optimize this flow throughout your organization.

Keep in mind that the value stream map should allow you to easily identify the value-enabling activities, the value-adding activities, and the non-value adding activities.

The goal of this tool is to eliminate all the non-value adding activities as well as eliminate all the wait times between consecutive steps in your processes.

Why should you get a Six Sigma certification?

#4: Regression Analysis:

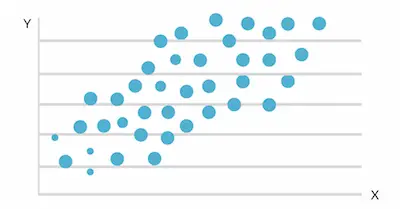

Simply put, a regression analysis is a statistical process that allows you to estimate and understand the relationship between different variables.

The truth is that when you graph these inputs and outputs, you will be able to visualize patterns that you wouldn't see in another way.

RSS Feed

RSS Feed