How to Implement TPM

#1: Announce The Plans For TPM Implementation:

Discover the pillars of TPM.

#2: Make Use Of A Pilot TPM Program:

#3: Focus On Restoring Targeted Equipment To Prim Working Condition:

Your focus should go first to the execution of an autonomous maintenance program, and then provide the needed training to equipment operators.

Learn more about the TPM process.

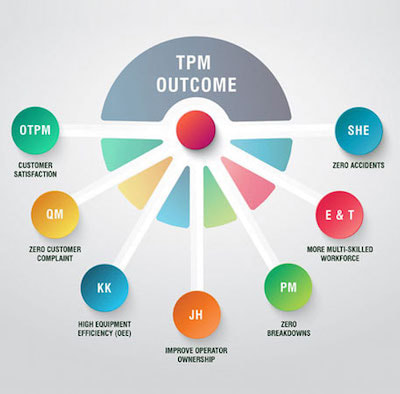

#4: Start Measuring Overall Equipment Effectiveness (OEE):

#5: Adress Major Loss Causes:

#6: Implement Proactive Maintenance:

In the end, there should also b taken the time to implement a feedback process that will allow you to continuously track your TPM program effectiveness.

Discover the tips of maintenance under the TPM process.

RSS Feed

RSS Feed