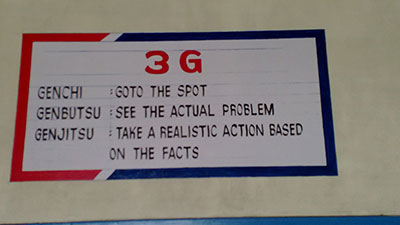

Gemba, Gembutsu, Genjitsu - The 3 G Of Kaizen

Check out the ultimate Six Sigma guide you need.

Read more about Kaizen and Kaizen Blitz.

So, what exactly are Gemba, Gembutsu, Genjitsu?

#1: Gemba – The Shop Floor

In case you already heard about Gemba, you probably already heard about the Gemba Walk. What the Gemba Walk means is simply to have the managers, leaders, or decision makers go to the shop floor where the real work is done. So, instead of managers and leaders to stay in their offices and get the information only from workers, they should take the time and see how things are done on the shop floor.

Should you get Six Sigma certification?

#2: Gembutsu – The Actual Product

The truth is that one of the main concerns of managers and leaders needs to be the quality of the products they sell. So, they need to make sure that they review the finished products to be certain that they have the quality required by customers. However, the Gembutsu goes a bit further. After all, managers and leaders need to check the product at their different stages. This will allow them to notice if there is any quality issue with the product. This will also be extremely helpful to determine where there might be a flaw within the process in a quick way.

One of the major benefits of using Gembutsu is that it allows managers and leaders to see where the real value of the product is created and, this way, they will be able to determine where they can save time and money.

#3: Genjitsu – The Facts

One of the things that you need to know about the Genjitsu is that it isn't meant to point fingers or blame someone for anything. This is simply the step required to get more information that can help managers and leaders make the necessary changes to eliminate waste when possible as well as to avoid problems.

How much can you expect if you are a Six Sigma black belt?

Gemba, Gembutsu, Genjitsu - The 3 G Principles

In case you want to start applying the Gemba, Gembutsu, Genjitsu, the truth is that all it takes s for managers and leaders to get out of their offices and go to where the real work is done. By observing everything, they will be able to gather a lot of precious information and data that will serve them to make better decisions to eliminate waste as well as to improve efficiency.

RSS Feed

RSS Feed