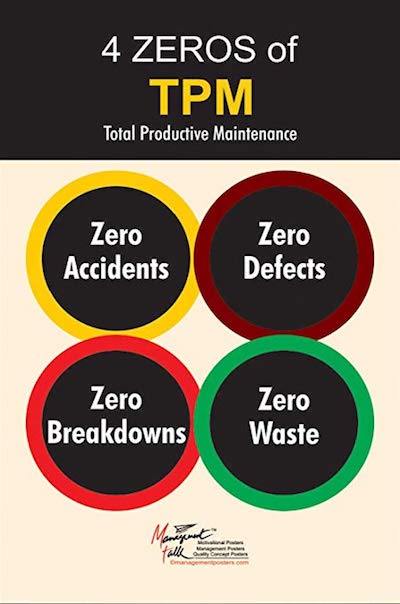

TPM or Total Productive Maintenance program has the main goal of helping professionals achieve the goals that are set for a higher rate of utilization and productivity.

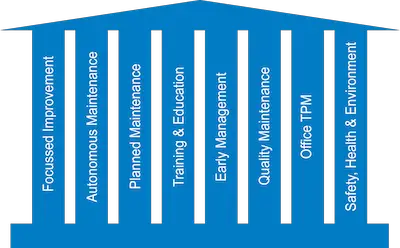

However, in order to start implementing TPM, there are 8 supporting pillars that you need to know about.

However, in order to start implementing TPM, there are 8 supporting pillars that you need to know about.

8 Supporting Activities Of The TPM

#1: Focused Kaizen:

During this first activity, you need to identify the problems related to equipment failures as well as set improvement goals in the kaizen event. The most important aspect during this stage is to ensure that the entire team is working together so that they can be able to discover the root of the problem and apply the solutions needed to the continuous improvement.

Learn more about TMP here.

Learn more about TMP here.

#2: Autonomous Maintenance:

During this second activity of the TPM, the operators of the machines are the ones responsible for any machine adjustments that are required as well as for the minor maintenance of that specific machine. This may include cleaning, inspection, and lubrication.

#3: Planned Maintenance:

This activity of the TPM includes both preventive as well as predictive maintenance routines that should be based on the monitoring of the machines' behavior. The goal of scheduled maintenance is to make sure that no major breakdowns occur as well as to reduce the number of unplanned stops. So, this should lead to an increase in the productive capacity.

Looking to know more about TPM?

Looking to know more about TPM?

#4: Education And Training:

The goal of this activity in TPM is to make sure that there is a continuous improvement of the skills of the employees.

#5: Early equipment Maintenance:

The main objective here is to ensure that in the design stage, the piece of equipment that is added needs to be easy to maintain and operate. This includes the lubrication, cleaning, inspection, and even the accessibility of the machine's parts.

#6: Quality Maintenance:

When you implement the TPM process, you want to make sure that you get only quality products at the end. So, as it is easy to understand, this activity serves to detect and prevent errors during the production. So, by using lean tools such as andon and jidoka, machines will be able to detect and report when there is any abnormal condition.

This is what you need to know to start implementing TPM.

This is what you need to know to start implementing TPM.

#7: The TPM Administration:

This is often an activity that is forgotten but is incredibly important. After all, the goal of the TPM administration is to improve the order processing procedures, the procurement, and even the scheduling. The main idea remains the same: waste elimination.

#8: Safety, Health, And Environment:

The last activity of the TPM is to set standards for the working conditions of all employees. This ensures that there is an elimination of potential health and safety risks. These can include the implementation of work standards or guards to ensure that all the machines are safe to use.

Bottom Line

While these may seem a lot to learn, the truth is that there are many advantages when you implement TPM. After all, some of the main benefits that this implementation can bring to your company include cost savings, more efficient workforce, optimized working schedule for all employees, equipment reliability, safer and cleaner workplace, and minimized delays, breakdowns, and production stops.

RSS Feed

RSS Feed