As you probably already know, Design for Six Sigma (DFSS) is an approach to product development that complements the Six Sigma problem-solving methodology. Ultimately, it includes redesigning or changing the core structure of a product or process.

So, the Design for Six Sigma (DFSS) has one main goal - to design it right the first time. And this is to ensure that there are any painful downstream experiences.

So, the Design for Six Sigma (DFSS) has one main goal - to design it right the first time. And this is to ensure that there are any painful downstream experiences.

5 Most Popular Design for Six Sigma (DFSS) Methodologies

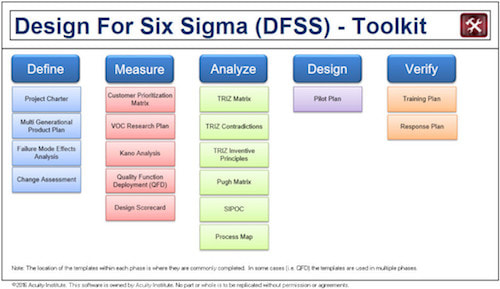

#1: DMADV (Define, Measure, Analyze, Design, Verify):

According to this Design for Six Sigma (DFSS) methodology, you will need to mainly focus on developing new products, services, or processes instead of redesigning them. So, you can then use this approach when you are actually executing new strategies or initiatives.

This methodology can be applied to non-existent processes or products requiring development as well as to existing products or processes that still need to meet the Six Sigma level.

Learn more about design for six sigma.

This methodology can be applied to non-existent processes or products requiring development as well as to existing products or processes that still need to meet the Six Sigma level.

Learn more about design for six sigma.

#2: IDDOV (Identify, Define, Develop, Optimize, And Verify):

Ultimately, this methodology involves all the main framework for product development as well as it uses steps to accomplish Six Sigma.

According to this strategy, you will need to first identify the client needs and translate them into design product, define all the product specifications the consumer needs, develop the actual product based on all the requirements, and, finally, optimize the design at the output to create the idea.

Looking to understand more about DFSS?

According to this strategy, you will need to first identify the client needs and translate them into design product, define all the product specifications the consumer needs, develop the actual product based on all the requirements, and, finally, optimize the design at the output to create the idea.

Looking to understand more about DFSS?

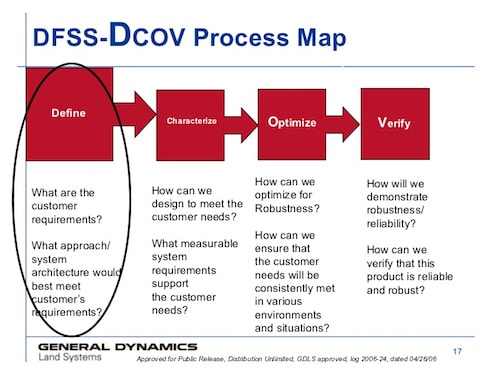

#3: DCOV (Define, Characterize, Optimize, Verify):

According to this methodology, you will need to first identify the Critical to Satisfaction (CTS) drivers and establish an operating window. Simply put, in the first stage, you are required to create a complete distinction between 3 different areas: inputs, actions, and outputs. On the next step, you will need to complete, using a two-step approach, system design, and functional mapping. The goal here is to characterize the design robustness. You will then need to optimize to improve the robustness and, finally, you are required to verify. The goal is to confirm both the capacity and product integrity over time.

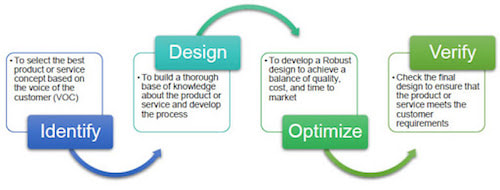

#4: IDOV (Identify, Design, Optimize, Validate):

IDOV is definitely one of the most popular Design for Six Sigma (DFSS) methodologies. When using this strategy, you will start by getting a formal design that involves your development team gathering competitive analysis, performing, VOC, and developing CTQs. On the next step, you take what you got from the CTQs highlights and include classifying functional requirements, evaluating alternatives, developing substitute concepts, and selecting the best-fit. You will then need to optimize the design using different tools such as forecasting performance, process capacity data and statistical method to tolerancing, and even developing large design elements. Finally, you will need to test and validate the design.

Learn more about DFSS six sigma.

Learn more about DFSS six sigma.

#5: DCCDI (Define, Customer, Concept, Design, Implementation):

When looked at closely, you will see that this methodology is very similar to the SMADV. However, it is worth pointing out that the implementation stage is the only addition to this methodology that is linked to the formation and commercialization of a good or service.

RSS Feed

RSS Feed