When you have a company, then you may be wondering if it is a good idea to simply implementing six sigma. After all, you keep seeing and reading about companies that enjoyed a huge success and others that failed miserably. And if you are going to try it, you need to be one of the successes, not failures.

Learn everything you need to know about six sigma.

Back in 1986 when Motorola decided to implement six sigma, the reactions were pretty mixed. There were mainly two different ideas: the ones that saw this as a complicated process that wouldn't lead to improved profits and the ones that saw it as a revolutionary system that could improve efficiency as never seen before.

Fast-forwarding some decades, we can now see that the strategy was actually pretty successful. After all, it was a revolutionary tool that allowed Motorola to identify and eliminate the causes of errors and defects in the manufacturing process as a way to meet and even exceed customer requirements.

Understanding DFSS six sigma.

Learn everything you need to know about six sigma.

Back in 1986 when Motorola decided to implement six sigma, the reactions were pretty mixed. There were mainly two different ideas: the ones that saw this as a complicated process that wouldn't lead to improved profits and the ones that saw it as a revolutionary system that could improve efficiency as never seen before.

Fast-forwarding some decades, we can now see that the strategy was actually pretty successful. After all, it was a revolutionary tool that allowed Motorola to identify and eliminate the causes of errors and defects in the manufacturing process as a way to meet and even exceed customer requirements.

Understanding DFSS six sigma.

So far, many organizations have tested six sigma, as demonstrated by the University of Nebraska-Lincoln through a study they did to establish underlying factors impacting an organization’s adoption of Sigma, and subsequent long-term success.

Their findings indicated a significant difference between companies that had successfully implemented Six Sigma and those that were yet to do so. About 64% of the successful cases overwhelmingly increased their profits by more than 100%, while 64% of the latter registered comparatively low profits.

One of the most interesting facts that were recorded is the fact that about 81% of the companies that were yet to successfully implement Six Sigma had registered significantly higher profits before adopting the strategy.

So, should you implement six sigma in your company?

Learn more about the DFSS methodology.

Their findings indicated a significant difference between companies that had successfully implemented Six Sigma and those that were yet to do so. About 64% of the successful cases overwhelmingly increased their profits by more than 100%, while 64% of the latter registered comparatively low profits.

One of the most interesting facts that were recorded is the fact that about 81% of the companies that were yet to successfully implement Six Sigma had registered significantly higher profits before adopting the strategy.

So, should you implement six sigma in your company?

Learn more about the DFSS methodology.

The Upside Of Six Sigma

Implementing six sigma is a gradual process that evolves to all organization levels. As you include six sigma in your business' culture, you will then be able to monitor closely your processes as a way to identify and correct problems as they emerge.

Ultimately, you will try to identify and eliminate problems before they even occur. And this leads to savings in both time and money. So, you should then start seeing increased profits and reduced operational costs within your business.

One of the main advantages of using six sigma is the fact that it relies a lot on data. So, you will be able to monitor your processes in real-time allowing you to make decisions faster.

Finally, by documenting your processes and defects, you’ll be setting up a learning platform, where lessons are shared by experts and other employees in a bid to improve their individual assembly lines.

Take a look at DFSS explained.

Ultimately, you will try to identify and eliminate problems before they even occur. And this leads to savings in both time and money. So, you should then start seeing increased profits and reduced operational costs within your business.

One of the main advantages of using six sigma is the fact that it relies a lot on data. So, you will be able to monitor your processes in real-time allowing you to make decisions faster.

Finally, by documenting your processes and defects, you’ll be setting up a learning platform, where lessons are shared by experts and other employees in a bid to improve their individual assembly lines.

Take a look at DFSS explained.

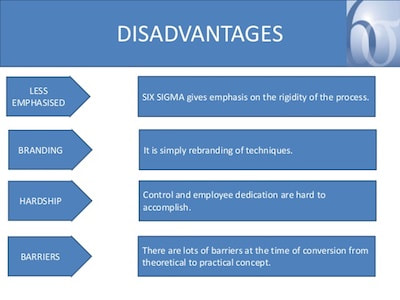

The Downside Of Six Sigma

One of the things that you need to keep in mind about six sigma is the fact that it is mainly a strategy to improve quality and not to reduce costs. Therefore, you may not even be able to see a cost reduction or you may even see them increasing when you implement six sigma.

RSS Feed

RSS Feed