One of the first things that you need to understand about Cost Of Quality (COQ) is that the calculating method varies from company to company.

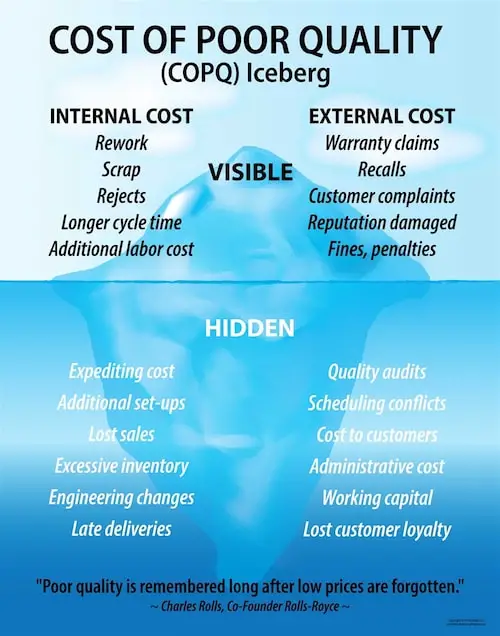

One of the methods that is sometimes used is to determine the Cost Of Quality (COQ) by calculating total warranty dollars as a percentage of sales. Unfortunately, this method is only looking externally at the Cost of Quality and not looking internally. So, when you want to get a better understanding, you need to ensure that you take a closer look at all the quality costs.

Looking to know more about six sigma?

One of the methods that is sometimes used is to determine the Cost Of Quality (COQ) by calculating total warranty dollars as a percentage of sales. Unfortunately, this method is only looking externally at the Cost of Quality and not looking internally. So, when you want to get a better understanding, you need to ensure that you take a closer look at all the quality costs.

Looking to know more about six sigma?

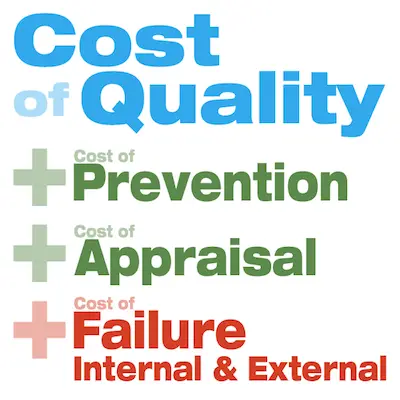

Ultimately, the Cost Of Quality (COQ) can be divided into 4 main categories: Prevention, Appraisal, Internal Failure, And External Failure. As you can imagine, all these categories are very broad and there are numerous sources of costs that are related to both good and poor quality.

So, let's take a look at some of the typical sources of Cost Of Quality (COQ).

So, let's take a look at some of the typical sources of Cost Of Quality (COQ).

Typical Sources Of Cost Of Quality

The Cost Of Good Quality:

#1: Prevention Costs: These are the costs that are incurred from activities that intend to keep failures to a minimum. These may include:

What is appraisal cost?

- new product development and testing

- quality planning

- development of a Quality Management System

- establishing product specifications

- proper employee training.

What is appraisal cost?

#2: Appraisal Costs: These are the costs that are incurred by a business to maintain product quality levels that are acceptable. These include:

Learn more about the appraisal cost.

- check fixtures

- process controls

- quality audits

- incoming material inspections

- supplier assessments.

Learn more about the appraisal cost.

The Cost Of Poor Quality

#1: Internal Failures: These are the costs that are linked with defects that are found before the service or product reaches the customer. These may include:

Discover more about appraisal cost 6 sigma.

- product re-work

- waste due to poorly designed processes

- machine breakdown due to improper maintenance

- excessive scrap

- costs associated with failure analysis.

Discover more about appraisal cost 6 sigma.

#2: External Failures: These are the costs that are linked with defects that are found at a later time. They are found after the customer receives the service or product. These may include:

- customer complaints

- warranty claims

- incomplete BOMs

- service and repair costs

- shipping damage due to inadequate packaging

- incorrect sales orders

- product or material returns.

How to Measure Cost of Quality (COQ)

As you can easily understand, all these costs that we have mentioned above have an influence on the Cost Of Quality (COQ). So, they need to be applied to the original Cost Of Quality (COQ) equation.

In case you don't know or don't remember, the original equation of the Cost Of Quality (COQ) is equal to the sum of the Cost of Good Quality and the Cost of Poor Quality. So, we now need to add the different categories of costs that we mentioned above. Therefore:

The Cost of Good Quality is the sum of Prevention Cost and Appraisal Cost:

CoGQ = PC + AC

The Cost of Poor Quality is the sum of Internal and External Failure Costs:

CoPQ = IFC + EFC

So, when you combine both equations, you can then get a more accurate Cost Of Quality (COQ):

Cost Of Quality (COQ) = (PC + AC) + (IFC + EFC)

In case you don't know or don't remember, the original equation of the Cost Of Quality (COQ) is equal to the sum of the Cost of Good Quality and the Cost of Poor Quality. So, we now need to add the different categories of costs that we mentioned above. Therefore:

The Cost of Good Quality is the sum of Prevention Cost and Appraisal Cost:

CoGQ = PC + AC

The Cost of Poor Quality is the sum of Internal and External Failure Costs:

CoPQ = IFC + EFC

So, when you combine both equations, you can then get a more accurate Cost Of Quality (COQ):

Cost Of Quality (COQ) = (PC + AC) + (IFC + EFC)

RSS Feed

RSS Feed